In the back-reflection Laue method the film is placed. This is particularly useful in the case of polycrystalline samples, multi phased alloys, where grain analysis, seed growth mechanism can be refined and modelled. This method is so called because the diffracted beams are partially transmitted through the crystal. Unlike EBSD, grain orientation maps can be generated from large scale samples using automatic scanning routines. Our tool delivers orientation accuracy down to 0.05 degree, this is critical for semiconductor detectors, laser or gamma scintillation materials, ceramics and thin films. There are no requirements to rotate the sample against any axis to find out any crystal orientation that would enable specific optical, magnetic or electronic transport properties. The standing X-ray wavefield intensity of a single crystal, under dynamical diffraction conditions, is directly measured by setting a 50 m-thick single-crystal CCD detector chip in nondispersive back-diffraction geometry. A back reflection geometry is used to record as many Bragg reflections as possible within a single exposure onto a CMOS based detector. Using a polychromatic “white” beam configuration, our tool focuses a beam down to <200 microns spot size onto a single crystal material.

#Back reflection laue method software#

This information is piped to a computer running NorthStar 7 - the latest version of our powerful orientation software - and is displayed in real time.Laue diffraction is a powerful method for investigating crystal orientation Back Reflection Versus Transmission Laue The Laue method can be split into two categories: back reflection and transmission. The interpretation of back-reflection Laue patterns is facilitated by using the Greninger chart.

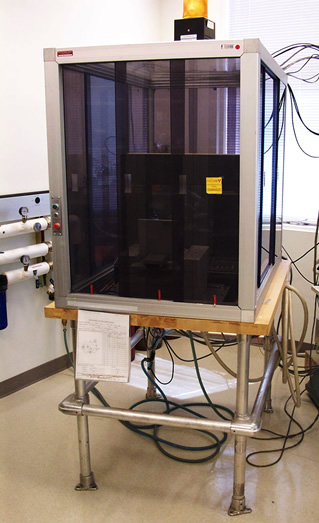

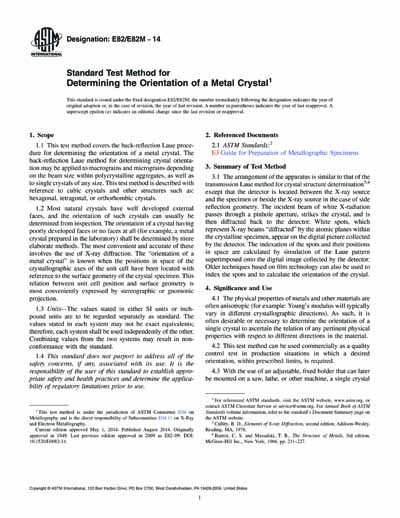

The Laue method has two different configurations, depending on the relative locations of X-ray source, crystal, and film: transmission Laue method and back reflection Laue method. These X-rays then reflect off the sample back to the detector where the diffraction pattern is collected. This is because the materials to be analyzed are single crystals. The MWL120 system uses the back-reflection Laue method. The Laue camera interfaces with an X-ray tower and collimates the beam through the center of the camera toward the crystal sample. With the MWL120 system, Laue images are displayed in real-time on a computer screen as the. The MWL120 real-time camera is designed to eliminate the need for X-ray film while enjoying improved collection speed and economic efficiency. Manipulate the orientation of a crystal sample using our joystick-controlled motorized stages and see the diffraction pattern move in real time on a computer monitor to rapidly characterize or determine the orientation of the crystal's lattice planes. The back-reflection Laue method is an indispensable tool for orienting single crystals in research and industry. In each, the film is flat and placed perpendicular to the incident beam. The MWL120 allows an operator to orient single crystals quickly and easily. Laue method back-reflection There are two variations of the Laue method, depending on the relative positions of source, crystal, and film (Fig. Ideal for industrial process control, research applications, or academic laboratoriesĮarlier model MWL110 systems can be upgraded to 120 capability

Provides an accuracy of 0.25° in standard mode and 0.05° in high-resolution modeĪpplications include: silicon, gallium arsenide, high- T c superconductors, sapphire, geological minerals, turbine blades, etc. triclinic crystal systems and generates stereographic projections The diffracting planes in the crystal are determined by knowing that the normal to the diffracting plane bisects the angle between the incident beam and the diffracted beam. The back-reflection Laue method for determining crystal orientation (1, 2) may be applied to macrograins (3) (0.5-mm diameter or larger) within polycrystalline aggregates, as well as to single crystals of any size. This is useful if the sample is too thick for X-rays to transmit through it. Northstar 7 software indexes Laue images from cubic, hexagonal. The Laue back reflection mode records X-rays scattered backwards from a broad spectrum source. It was made successful in this case by application to metal crystals with small spacings. Ideal replacement for the Polaroid XR-7 back-reflection cassette (film no longer available) In the back-reflection Laue method the film is placed between the crystal and the x-ray source, the incident beam passing through a hole in the film.

0 kommentar(er)

0 kommentar(er)